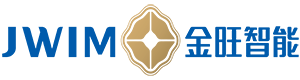

LP-200FΑυτοματοποιημένη μηχανή αποκωδικοποίησης μπουκαλιών

1Εισαγωγή

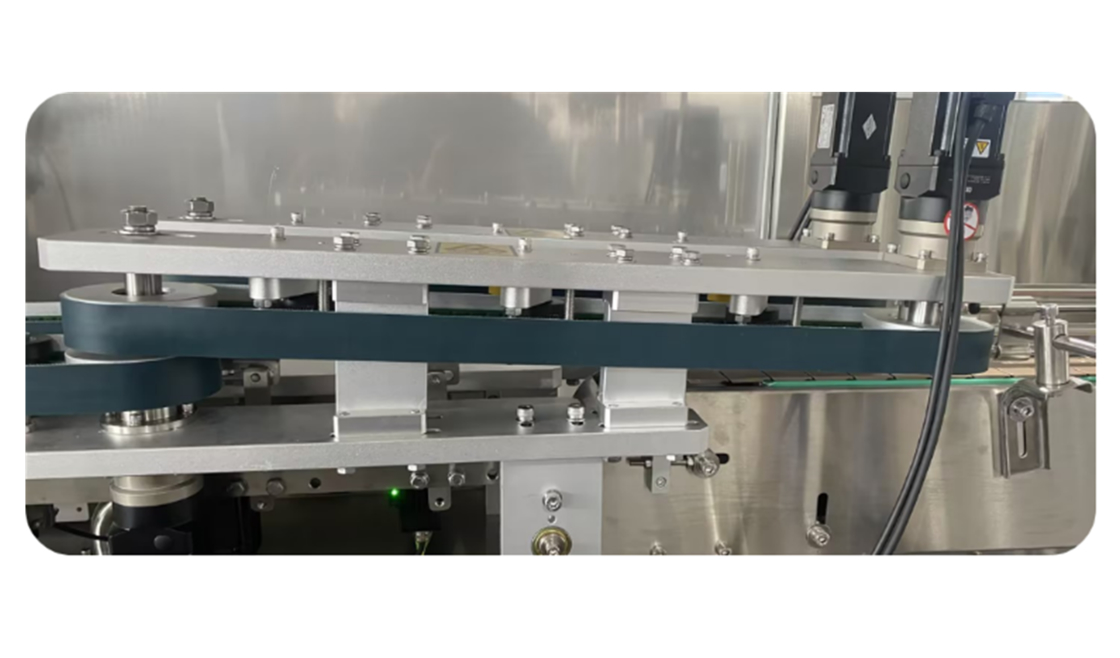

Το πλήρως αυτόματο μηχάνημα διαλογής μπουκαλιών LP-200F αποτελείται από μηχανή φόρτωσης μπουκαλιών, πίνακα περιστροφής διαλογής μπουκαλιών, εξαρτήμα αφαίρεσης μπουκαλιών, εξαρτήμα διαλογής μπουκαλιών,ένα εξαρτήμα χύσης και απομάκρυνσης μπουκαλιών, ένα ηλεκτρικό κουτί, και μια οθόνη αφής.

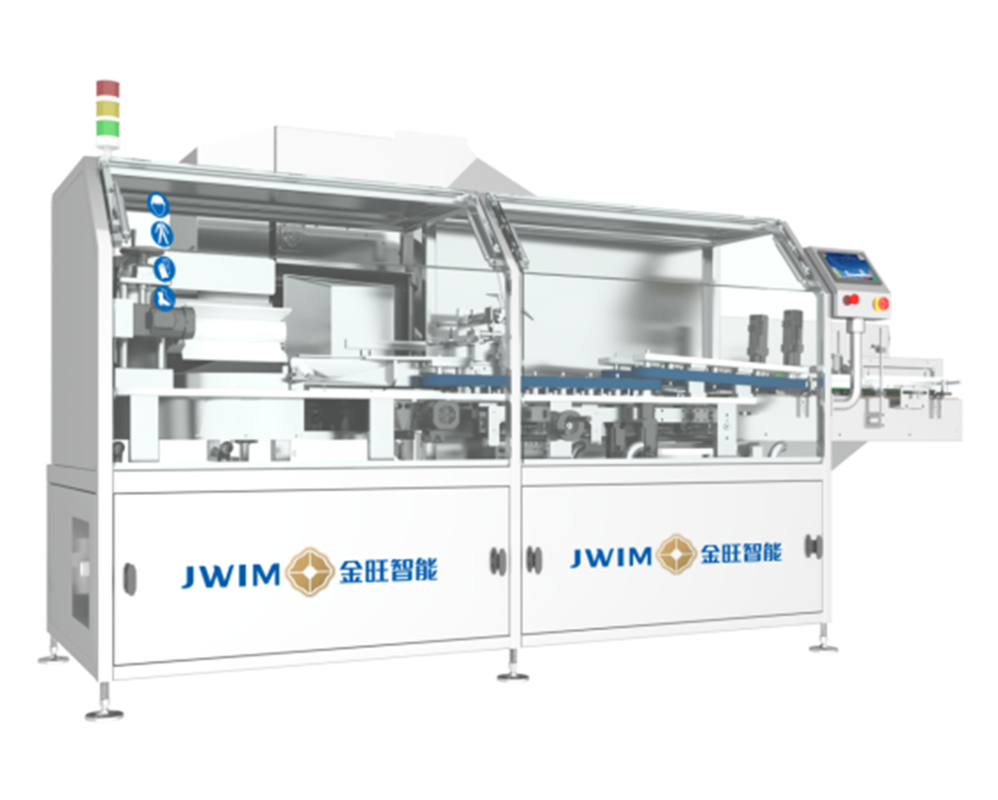

Ένας μεγάλος αριθμός ακατάτακτων μπουκαλιών τοποθετείται στον πίνακα περιστροφής διαλογής μπουκαλιών από τον τροφοδότη μπουκαλιών και μεταφέρεται στον χώρο διαλογής μπουκαλιών μέσω της ιμάντα μεταφοράς,ώστε οι φιάλες να μπορούν να μεταφέρονται κατακόρυφα στην ιμάντα μεταφοράς του χρήστηΤο μοντέλο αυτό χρησιμοποιεί έλεγχο κινητήρα σερβο για τη διαλογή και διανομή μπουκαλιών, το οποίο είναι σταθερό και αξιόπιστο.

2. Σχέδιο διαστάσεων εξοπλισμού

3.Τεχνικές παραμέτρους

| 1 |

Ταχύτητα μπουκαλιού UΣκάνδαλο.r |

50 ml: ≤ 12000φιάλες/h; 250 ml: ≤ 9000φιάλες/h

1000 ml:≤6600φιάλες/h

*Η πραγματική χωρητικότητα ποικίλλει ανάλογα με το μέγεθος του προϊόντος, το υλικό συσκευασίας κλπ. |

| 2 |

Μέγεθος μπουκαλιού |

Στρογγυλά, επίπεδα και τετραγωνικά μπουκάλια:ΔιάμετροςΦ40-95mmΥψόμετρο80-240 χιλιοστά |

| 3 |

GωςΠανασφάλεια |

00,6-0,8MPa |

| 4 |

Πηγή ενέργειας |

~220V 50Hz/1,98KW |

| 5 |

Εξωτερική διάσταση(περιλαμβάνουνΜηχανή τροφοδοσίας μπουκαλιών) |

3430 × 1755×1860 χιλιοστά(Α×Π×Χ) |

| 6 |

Εξωτερική διάσταση(να αποκλείσειΜηχανή τροφοδοσίας μπουκαλιών) |

2730 × 1450 × 1530 χιλιοστά(Α×Π×Χ) |

| 7 |

Βάρος |

730kg+189kgΜηχανή τροφοδοσίας μπουκαλιών) |

4. Ηλεκτρική διαμόρφωση

5. Εφαρμόσιμο μέγεθος φιάλης

Χρησιμοποιείται ευρέως στα γεωργικά χημικά,κτηνίατρος,Τεχνική βιομηχανία, καθημερινή χημική, λιπάσματα, πετρέλαιο και άλλες βιομηχανίες 50-1000ml μπουκάλια αυτόματη μπουκάλιΑνακωδικοποιητής.

6. Δρομές διαδικασιών

7. Πλεονέκτημα

7.1.Αυτό το μοντέλο χρησιμοποιεί έλεγχο με κινητήρα εφοδιασμού για τη διαλογή και διάθεση μπουκαλιών, το οποίο είναι σταθερό, αξιόπιστο και έχει καλό αποτέλεσμα διαλογής μπουκαλιών.

7.2.Δυνατή καθολικότητα:Η αλλαγή των προδιαγραφών δεν απαιτεί αλλαγή καλούπιων, καθιστώντας τις προσαρμογές βολικές και γρήγορες.Απλώς αλλάξτε τον αριθμό των ταινιών στο εσωτερικό του δίσκου και ρυθμίστε τη ζώνη διαλογής μπουκαλιών για να δείτε το πλάτος.

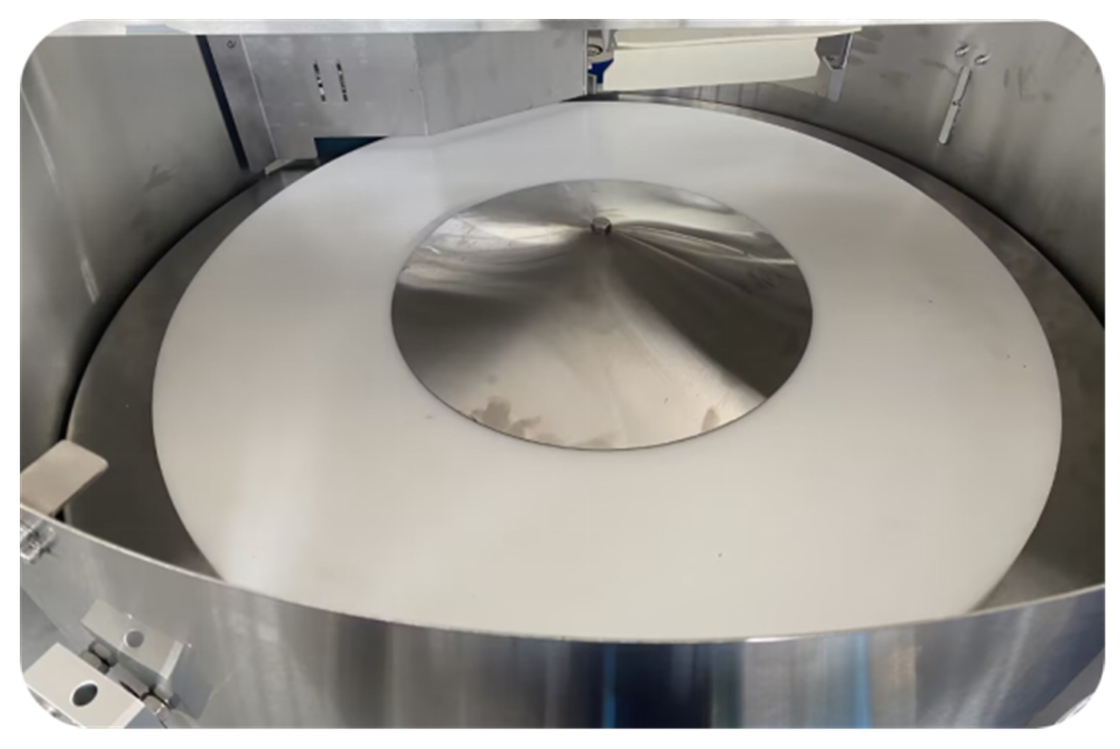

7.3. Πιο σταθερή χορήγηση μπουκαλιών:Η κλίση της ζώνης διανομής μπουκαλιών μειώνει τη δύναμη απόσβεσης της μπουκαλιής όταν κλίνεται σε κατάλληλη γωνία σε σύγκριση με οριζόντια δομή.καθιστώντας το λιγότερο επιρρεπές στο τέρμα της φιάλης.

7.4.Λειτουργία αυτόματης τροφοδοσίας μπουκαλιού: Η λειτουργία αυτόματης τροφοδοσίας μπουκαλιών χρειάζεται μόνο να χύσει το μπουκάλι στο ανελκυστήρα μπουκαλιών, και το πίνακα περιστροφής είναι εξοπλισμένο με ανίχνευση φωτοηλεκτρικό,Για να πραγματοποιηθεί η αυτόματη τροφοδοσία με φιάλη όταν η φιάλη είναι ανεπαρκής, σταματά την τροφοδοσία με μπουκάλι όταν η μπουκάλα είναι αρκετή, όταν δεν υπάρχουν μπουκάλια στον ανελκυστήρα μπουκαλιών, συναγερμός αυτόματα χωρίς χειροκίνητη παρέμβαση.

7.5.Με εναρμόνιση της φωτοηλεκτρικής:Όταν η φιάλη της μεταγωγικής ζώνης πίσω από το κανάλι είναι συμφόρηση, σταματήστε τη φιάλη, όταν η μεταγωγική ζώνη πίσω από το κανάλι είναι ομαλή, ξαναφιάλη,για να επιτευχθεί η τέλεια σύνδεση με τον εξοπλισμό συσκευασίας πίσω από το κανάλι, μπορεί να συνειδητοποιήσει το σύνολο της μηχανής μη επανδρωμένη λειτουργία.

7.6Ανάλογα με την κατάσταση, μπορεί να είναι εξοπλισμένο με συσκευή φυσήγματος ή μηχανική συσκευή απόρριψης μπουκαλιού: όταν υπάρχει ένα αναποδογυρισμένο μπουκάλι, η συσκευή μπορείη συσκευή απόρριψης σπρώχνει αυτόματα το αναποδογυρισμένο μπουκάλι πίσω στην θήκη συλλογής.( Αυτή η λειτουργία είναι προαιρετική)

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!